Online

All Product Categories

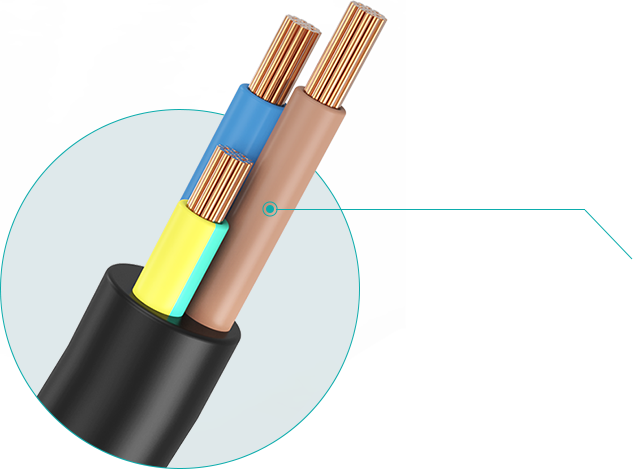

Fluoroplastic cable

Fluoroplastic materials have extremely high oxidation resistance and aging resistance

Fluoroplastic cable

Fluoroplastic materials have extremely high oxidation resistance and aging resistance

Other Product Cases

Step 1

Category

| Voltage | Type | Model |

| 450/750V |

KFF KFF9F KFFR KFV KFVR |

|

| Steel tape shielding |

KFFP KFFP2 KFFRP KFVRP KFVP |

|

| Armored |

KFF22 KFV22 |

|

| Fireproof | DJF4PF4P |

Step 2

Chip Count

1-64 cores (0.75 square to 6 square)

Step 3

Features

01

High temperature resistance

Fluoroplastic cables can withstand extreme high temperature environments, generally ranging from -60°C to 250°C, and some fluoroplastics (such as PFA) can even withstand higher temperatures. This allows them to operate stably in high-temperature industrial environments, aerospace, and high-temperature processing equipment.

02

Corrosion resistance

Fluoroplastic cables have excellent acid, alkali, and solvent resistance, and can work for a long time in environments with severe chemical corrosion. They are extremely resistant to most chemicals (such as oils, solvents, chemicals, etc.) and are suitable for use in chemical plants, oil drilling, laboratories, and other places.

03

UV resistance

Fluoroplastic cables can resist ultraviolet radiation and will not degrade even after long-term exposure to sunlight. They are suitable for outdoor or sunlight-exposed applications.

04

Low electrical loss

Fluoroplastic cables have very low dielectric constants and low electrical losses, making them suitable for the transmission of high-frequency signals, such as microwave signals, electromagnetic wave transmission, etc. This property makes them widely used in radio frequency (RF) and high-speed data transmission.

05

Excellent insulation

The insulation resistance of fluoroplastic cables is very high, usually up to 10^9 Ω·km, providing excellent electrical isolation effect, avoiding current leakage, and is suitable for high-voltage and high-frequency electrical equipment.

06

Abrasion resistance

The fluoroplastic outer sheath and insulation layer have excellent wear resistance, allowing the cable to be used for a long time in a mechanical friction environment without the risk of breakage or conductor exposure.

07

Anti-aging

Fluoroplastic materials have extremely high oxidation resistance and aging resistance, and can maintain stable physical properties and long service life even under extreme environmental conditions (such as high temperature, ultraviolet radiation or chemical exposure).

08

Low water absorption

Fluoroplastic cables absorb almost no water and have excellent moisture resistance. They can be used for a long time in a humid environment or underwater without affecting the performance of the cable.

09

Flame retardancy

Most fluoroplastic cables have good flame retardancy, which can effectively reduce the risk of fire spread and ensure the safety of the cable even in emergency situations such as fire.

10

Strong environmental adaptability

Fluoroplastic cables have strong environmental adaptability and can work continuously and stably in harsh environments such as extreme high temperature, low temperature, humidity, salt spray, ozone and radiation. Therefore, they are very suitable for military, aerospace, petroleum, chemical and other industries that require extreme environmental adaptability.

11

Long-term stability

Due to the chemical and physical stability of fluoroplastic cables, they can maintain excellent performance for a very long time, with a service life of up to decades, greatly reducing the frequency of replacement and maintenance costs.

12

Flexibility

Although the insulation layer and outer sheath of fluoroplastic cables are very strong, they are also relatively flexible and suitable for occasions that require frequent bending or movement, such as connections in precision instruments, robots and automation equipment.

Step 4

Specs

| Technical parameters | Specific description |

| Conductor material | Copper or tinned copper is usually used, which has good conductivity and avoids the attenuation of conductivity. |

| Insulation material | Common fluoroplastic materials: PTFE (polytetrafluoroethylene), FEP (fluorinated ethylene propylene copolymer), PFA (perfluoroolefin resin). |

| Operating temperature | -60°C to 250°C (depending on the material type, some high-performance fluoroplastic cables can withstand higher temperatures). |

| Withstand voltage | Usually 1000V to 3000V, suitable for most low-voltage and medium-voltage applications, and can withstand higher voltages in certain cases. |

| Dielectric constant | The dielectric constant is usually 2.1 to 2.3, and the lower dielectric constant is suitable for high-frequency signal transmission. |

| Insulation resistance | ≥10^9 Ω·km, providing excellent insulation performance and can effectively prevent current leakage. |

| Corrosion resistance | It has excellent corrosion resistance to most acids, alkalis, solvents and chemicals, and is suitable for harsh environments. |

| UV resistance | It can withstand ultraviolet radiation, suitable for outdoor environments, and maintain long-term stability. |

| Abrasion resistance | It has high wear resistance and is suitable for use in environments with large mechanical friction. |

| Flammability resistance | It has good self-extinguishing properties and is not easy to burn, suitable for use in occasions requiring fire protection. |

| Moisture resistance | It is not easy to absorb water, has good moisture resistance, and is suitable for use in humid environments. |

| Outer sheath material | According to the needs, the outer sheath can be made of fluoroplastics or other materials that are resistant to high temperature and chemical corrosion. |

| Electrical transmission performance | Low loss, suitable for high-frequency and high-speed data transmission, especially suitable for radio frequency and microwave cables. |

| Service life | Long life, fluoroplastic cables can work stably for a long time in extreme environments, and the service life can reach decades. |

| Application areas | Chemical, petroleum, aerospace, medical, electronic equipment, food industry, laboratories and other environments that require high corrosion resistance, high temperature and high voltage. |

WhatsApp

Email

WeChat

WhatsApp

Email

WeChat

Contact

You can contact us through the following four methods, and we will get in touch with you immediately after receiving your inquiry!

Call us

Send Email

Leave a Message

Add WeChat or WhatsApp