Online

All Product Categories

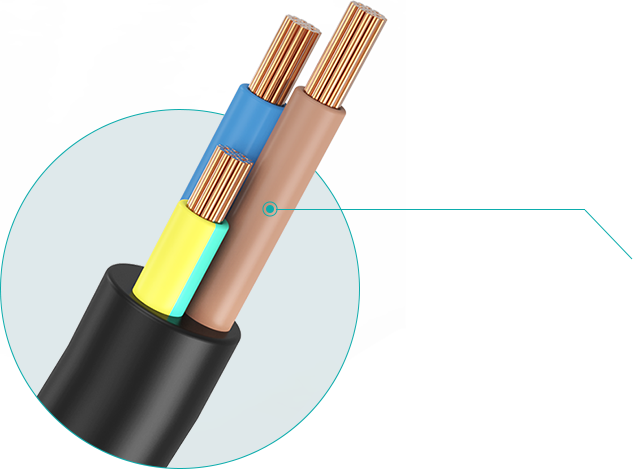

Low voltage cable 1.8-3KV

Applicable to underground power systems, aerial installation, cable trenches, pipelines and other laying methods

Low voltage cable 1.8-3KV

Applicable to underground power systems, aerial installation, cable trenches, pipelines and other laying methods

Other Product Cases

Step 1

Category

| Voltage | Outer layer | Model | Grade |

| 450/750V 300/V |

With armor |

YJV YJLV |

Flame retardant N fireproof RCA grade |

| Without armor |

Step 2

Chip Count

1-5 core

Step 3

Features

01

Safety and reliability

The cable uses cross-linked polyethylene (XLPE) as the insulation material, which has excellent electrical insulation performance, can withstand high voltage, and has good heat resistance, ensuring the safe operation of the system in high temperature environments. XLPE also has strong fire resistance and anti-aging ability, reducing the risk of fire and failures caused by cable aging. In the armor design (such as steel belt armor), it has greater tensile strength and compressive resistance, which can effectively protect the cable from external mechanical damage, especially suitable for laying in an environment susceptible to external interference.

02

Superior electrical performance and high conductivity

The use of high-quality copper or aluminum conductors ensures that the cable has excellent conductivity, can efficiently transmit electricity, and reduce power loss. Copper conductors provide lower resistance and are suitable for high-load power systems, while aluminum conductors have more advantages in cost and weight. The high current carrying capacity of the cable is suitable for places where high-power current transmission is required, such as industrial equipment and high-load power systems.

03

Long service life and low maintenance cost

The cross-linked polyethylene insulation material of 1.8/3kV power cable has the characteristics of UV resistance, strong temperature resistance and oxidation resistance, which can effectively extend the service life of the cable. Even in extreme working environments, the cable can maintain a long reliable operation period, reducing the frequency of replacement and maintenance, and reducing maintenance costs.

04

Strong adaptability and multiple laying methods

This cable has strong adaptability and is suitable for underground power systems, air installation, cable trenches and pipelines. It can ensure safe power transmission even in narrow, harsh or humid environments. It has a wide operating temperature range and can operate stably between -15°C and +90°C.

05

Environmental protection and energy saving

The cable is made of environmentally friendly and non-toxic materials, meets modern green building and environmental protection standards, and is suitable for places with high environmental protection standards. The high efficiency of conductors and insulation materials greatly reduces energy loss in power transmission and improves the overall energy saving efficiency of the system.

06

Good mechanical protection and corrosion resistance

The outer sheath of the cable is made of corrosion-resistant materials such as PVC, which can effectively prevent chemical corrosion in the environment. It also has tensile and compressive strength, reducing the impact of external physical factors on the cable. Armored cables provide stronger mechanical protection and are suitable for use in high-risk environments, such as heavy industrial areas and mining areas.

Step 4

Specs

| Technical Parameters | Description |

| Rated voltage | 1.8/3kV |

| Maximum working voltage | 3kV |

| Frequency | 50Hz |

| Conductor material | Copper (Cu) or Aluminum (Al) |

| Conductor specification | Usually range: 2.5mm² to 400mm², depending on the current capacity |

| Insulation material | Cross-linked polyethylene (XLPE) or polyvinyl chloride (PVC) |

| Insulation thickness | 1.5mm - 3.5mm |

| Sheath material | Polyvinyl chloride (PVC) or polyethylene (PE) |

| Sheath thickness | 1.2mm - 3mm |

| Electrical performance | Insulation resistance:>1000 MΩ·km, withstand voltage: AC 3.5kV, test duration 5 minutes |

| Minimum bending radius | 6 times the outer diameter of the cable |

| Tensile strength | 1000N to 5000N (selected according to size and application environment) |

| Operating temperature | -15°C to +90°C (XLPE) or -10°C to +70°C (PVC) |

| Minimum laying temperature | -5°C - -10°C |

| Cable type | Single-core cable, multi-core cable, armored cable, unarmored cable |

| Cable standard | GB/T 12706-2008, IEC 60502, UL standard |

| Application environment | Applicable to laying in underground, cable trench, pipeline, air, etc. Armored cable is suitable for more severe environment |

| Common cable specifications | 2.5mm²、4mm²、6mm²、10mm²、16mm²、25mm²、35mm²、50mm²、70mm²、95mm²、120mm², etc. |

WhatsApp

Email

WeChat

WhatsApp

Email

WeChat

Contact

You can contact us through the following four methods, and we will get in touch with you immediately after receiving your inquiry!

Call us

Send Email

Leave a Message

Add WeChat or WhatsApp